When I stripped my new one it was also bone dry inside,so lubrication is not high on their list of priorities at that particular factory!

I still shake my head in disbelief when I think of what it looked like when I first took it apart, I could’ve done it in white cotton gloves and they would’ve been virtually unmarked

Being s/h I don’t know the age or history but I can’t believe anyone would take it apart and leave it like that, I seriously think it might’ve been like it from new !

Thanks for reminding me about those washers, I’d forgotten, I did read about that tweak in an old thread when I was searching for info on the gun.

When I stripped my new one it was also bone dry inside,so lubrication is not high on their list of priorities at that particular factory!

This afternoons fettling has now produced an air gun that cocks and shoots !

I made another top hat, this time with a 16mm long spigot instead of 5mm. The head thickness remained the same as the previous one and I cut 20mm off the rear spring guide

I decided to size the piston washer by putting the piston in the lathe and using 400 wet&dry with some light gun oil on it, not sure if thatís the right thing to do but it seems to have worked and although the piston still isnít a Ďsliding down under gravityí fit, it is easier to get in and out.

I also removed two of the spring washers from the trigger mech as suggested and itís now a much lighter crisper let off

The cocking effort is still considerable, and Iím guessing the slightly tight piston and 5mm of preload isnít helping, but I feel Iím progressing in the right direction

I put a couple of shots through using the Falcon AP pellets and then recorded 12 results on the chrono, early days I know but you need a starting point !

It was originally shooting around 10.8 - 11ftlbs ĎDryí with a few FAPís I put through and Iím guessing the new tighter piston is reducing the power a little bit.

Am I right in thinking the power will go up a bit when the new piston seal wears in ? If so I might remove a coil from the spring to make cocking easier now, even after a dozen shots my elbows feeling it

Norm

594 - 10.5

601 - 10.7

592 - 10.5

595 - 10.5

601 - 10.7

592 - 10.5

583 - 10.1

580 - 10.1

592 - 10.4

583 - 10.1

587 - 10.2

591 - 10.4

588 - 10.3

Oh, nearly forgot thereís absolutely NO twang and very little recoil

Norm

Sounds like a job very well done, Norm; nice one.

Depending on the seal fit currently, yes, you'd usually expect power to rise with a little more use. Just sitting in the cylinder itself will help a little. I'd probably be tempted to give it a few hundred shots and recheck, as the output isn't overly high and those FAPs might be yielding the highest power.

THE BOINGER BASH AT QUIGLEY HOLLOW. MAKING GREAT MEMORIES SINCE 15th JUNE, 2013.

NEXT EVENT :- May 4/5, 2024.........BOING!!

My poor old knackered elbow

I may have to do that over the course of a week ( or two

) I won’t waste the FAP’s I’ve got loads of JSB’s so I’ll put some of those through. Not needing to run it over the chrono for that means I can put the silencer adapter and my HW silencer on so that’ll make it a bit easier to cock

Should be an interesting outcome when it’s finished, I’ll have to be careful I could get the fettling bug - and I’ve heard there’s no known cure

Might even treat myself to a Venoman setback trigger

Also had another small win this afternoon, Iíd previously bought a 15mm guntuff silencer adaptor from our sponsor for the Remington but it turned out the Remy barrel is 15.1mm

I found a small cylindrical metal grinder that fits in a cordless drill, it was about 14.8mm diameter and with some careful manoeuvring I managed to open up the diameter to 15.1mm, a perfect fit on the Remy

really interesting to read.

i have a Remington warhawk i bought a while ago as i wanted a normal rifle for garden targets shooting, my normal rifles are target types ( original 66 + walther cg90) plus some others.

i got the Remington as it felt like it was fairly basic but i have wondered if it would be tuneable, looking at your posts i think i'll be getting busy soon as it looks fun and i like tinkering!, has anyone else here messed about with a warhawk?

thanks all Dan

Good result, and you're right, tinkering can become a bit of addictive

I am nowhere near as knowledgeable as the many proper tuners on here, but one thing that I have learnt by tinkering with airguns and reloading for powder burners, only change one thing at once.

If you change one variable and it gets better or worse, you know what has caused the change, if you change 3 things at once and have a positive or negative result, you have no idea which change has caused it.

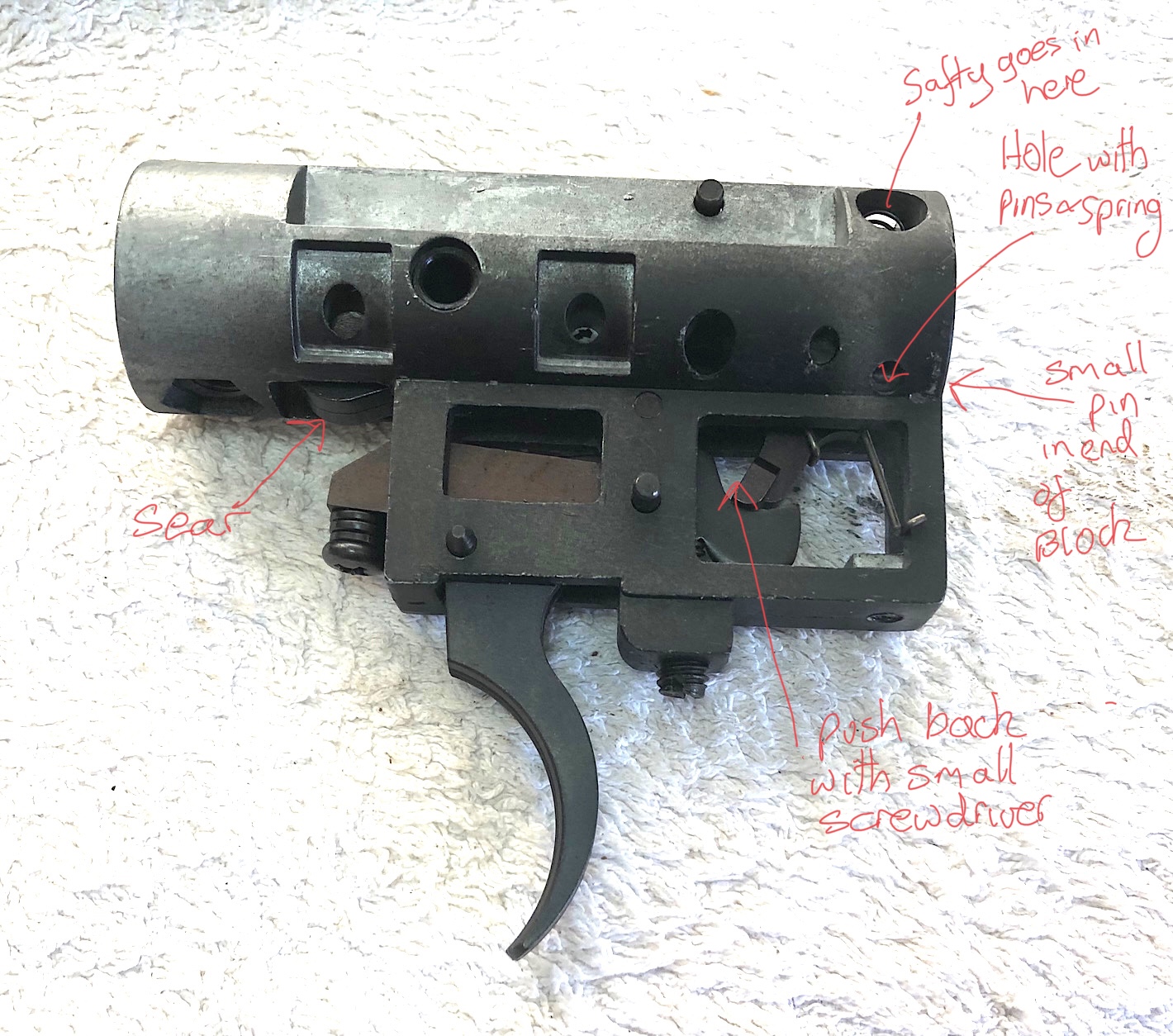

Not sure if it has the same trigger mechanism but if it has I found through searching on here that before you knock the two pins out that hold the trigger mech into the cylinder you need to remove the safety first. This is done by cocking the trigger ( without actually cocking the gun ), I used a piece of hardwood dowel to push the sear down and at the same time putting a small screwdriver in the cocking link and pushing back till it cocks.

Then where the small hole is below the safety lever there is a small thin pin which can be pushed out of the back far enough to pull it out the rest of the way with small pliers. Before you do this put your finger over the hole so the two small pins and tiny spring donít ping out. ( Iíve found in practice they donít tend to anyway but better safe than losing them. )

If they donít come out turn the trigger unit so they drop out, they come out pin/spring/pin in that order. Then you can pull out the safety with its spring.

Then with the cylinder in a spring compressor ( if thereís preload ) gently tap out the two big pins that hold the trigger into the trigger block.

Re assembly is the reverse and you have to cock the trigger and reassemble the safety first before putting the trigger back in the cylinder block and compressing it in so the main two pins can be reinserted.

Iím sure all this is already on here but it doesnít hurt for it to be part of this thread.

Of course if the Warhawk is different then this is no use to you at all

yes the triggers are nothing alike, the warhawk is pure budget and designed by an accountant!

i have been digging on the web and found that the war hawk is basically a hammerli hunter force 900, and there are a few interesting videos on these on youtube, i found one that shows a conversion to a 2 stage trigger made from basic bit and the original parts, simple stuff and i'll be giving it a go along with a polish and de-burr etc